Why use Senturi for Injection Molding?

Senturi has an intimate network of best-in-class molders that specialize in a variety of materials, part sizes, production volumes.

With Senturi, you get the expansive manufacturing expertise of our network while getting the customer support that is often times missing from the manufacturing industry. Your account manager will be in contact at every step of the process so you can rest assured that quality plastic parts will arrive exactly when you need them.

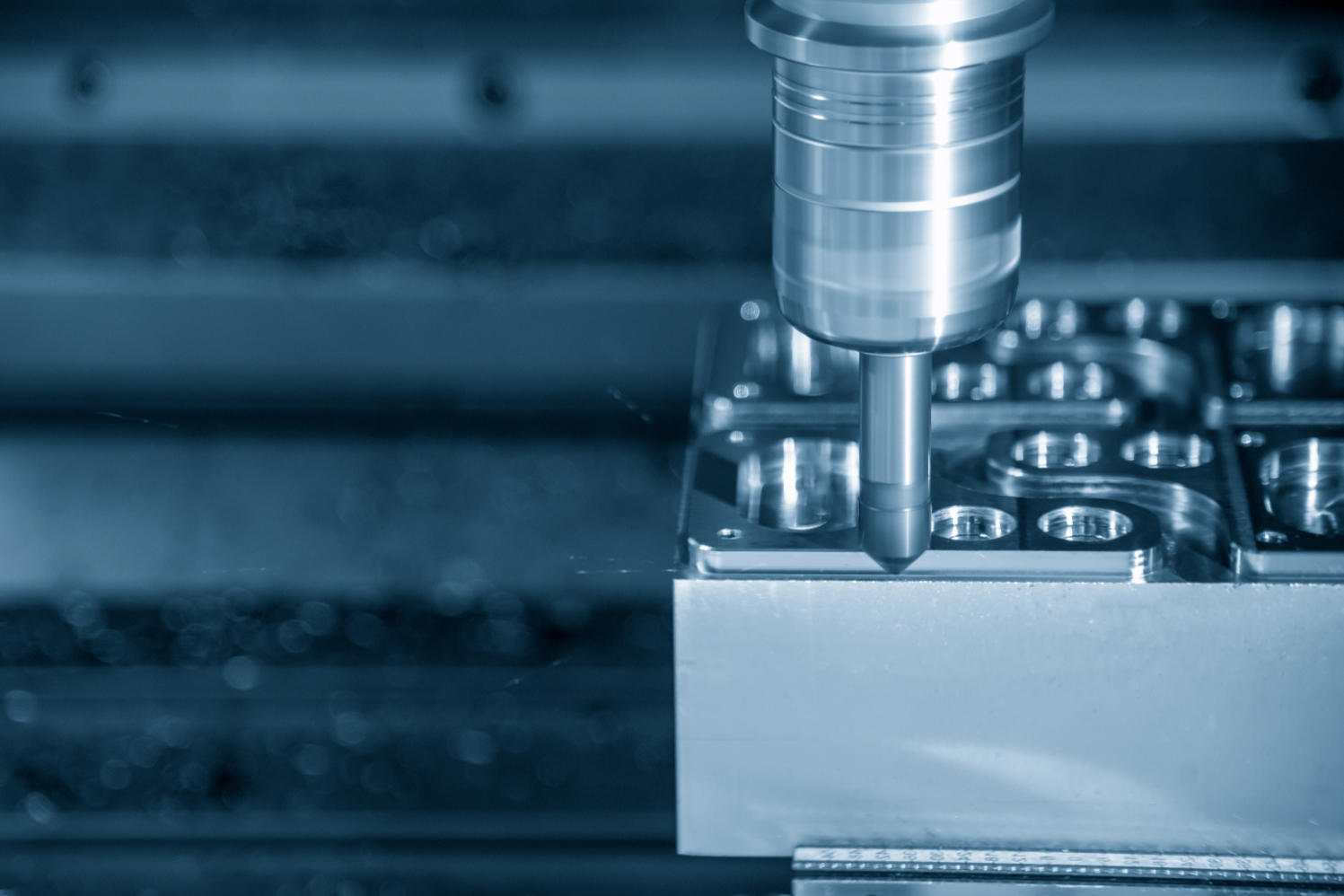

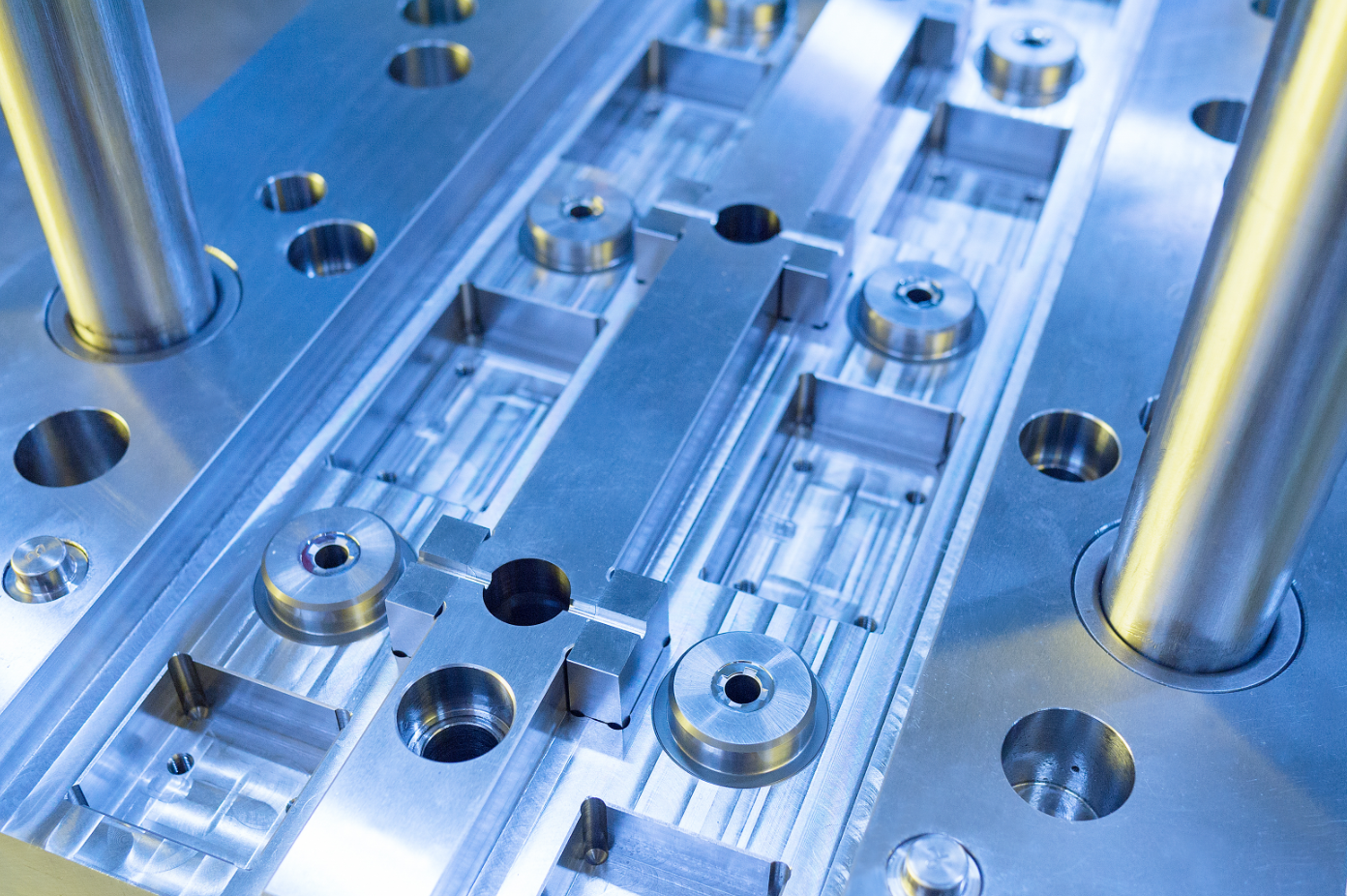

Injection Molding Capabilities

Senturi can help you with steel prototype tooling for up to 10,000 shots and high-quality steel production molds for projects requiring up to 1M shots.

Additionally, we have both single and multi-cavity molding capability to help minimize costs for high volume projects on shorter timelines.

If your designs has performance characteristics that no one material can satisfy, we welcome projects that require insert molding and overmolding.

| Project Guidelines | |

| Min Part Size | 0.15in x 0.10in x 0.24in 3.8mm x 2.5mm x 6mm |

| Max Part Size | 31.5in x 31.5in x 15.7in 800mm x 800mm x 400mm |

| Standard Tolerances | +/- 0.005in (Mold) +/- 0.13mm (Mold) +/- 0.002in (Resin) +/- 0.051mm (Resin) |

| Standard Lead Time | 10-15 days for T1 samples 5-15 days for production run |

Materials

We mold a variety of engineering-grade plastics. Check out our list of available materials below. If you do not see a specific material, reach out to our sales team to discuss specialty materials.

- Acrylonitrile Butadiene Styrene (ABS)

- Polyethylene (PE)

- Polypropylene (PP)

- Polycarbonate (PC)

- Nylon (PA6, PA6/6, PA 12)

- Polyurethane (PU)

- Polymethyl Methacrylate (PMMA)

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polystyrene (PS)

- Polyetheretherketone (PEEK)

- Polyoxymethylene (POM/Acetal/Delrin)

- Polyethylene Terephthalate (PET)

- Thermoplastic Elastomer (TPE)

- Thermoplastic Vulcanizate (TPV)

- Polyetherimide (PEI)

- Polysulfone (PSU)

- Liquid Silicone Rubber (LSR)

Additives like UV absorbers, flame retardants, plasticizers, colorants and glass fibers are also available.

Check out parts made of various materials in our parts gallery.

Finishes

Have unique finishing requirements? Our network has an array of capabilities to make sure your parts are finished to meet all your cosmetic and performance requirements.

- Color Matching

- SPI Standard Finishes

- Mold-Tech Texturing

- Painting

- Dip Coating

- Electroless Plating

- Plasma Treatment

- Adhesives

- Screen Printing

- Press-Fit Inserts

- Post-Process Machining

- Heat-Staking

- Ultrasonic Welding

- Pad Printing

- Light Assembly

- Production Assembly

Check out parts with various finishes in our parts gallery.

Frequently Asked Questions

What are the pros and cons of Injection Molding?

Injection molding is an extremely common manufacturing process because of all of its benefits. But you should carefully consider whether its the right technology for your projectt. Check out the pros and cons below:

Pros:

- Cost effective and efficient for production volumes. After the mold is cut and samples are approved, cycle times are in seconds.

- Additionally, family molds can be used to produce multiple parts at once.

- Tight tolerances can be achieved. Tolerances of +/-0.005 in are feasible.

- High repeatability. Steel production molds can last 100,000 -1,000,000 cycles depending on the type. This gives you a long lifespan of complying parts for your production projects.

Cons:

- Initial investment is high. The investment in the mold is high so you need to make sure your project is of sufficient volume to amortize that cost over production.

- Processes like urethane casting or 3D printing should be considered for early starge prototypes.

- Initial lead times are long. When an injection molded project is started, the mold must be cut and samples must be approved. This typically takes 4 weeks to complete before production runs are started.

- Design changes are costly. Design changes are extremely expensive. If you are lucky, the change is “steel safe” and the existing tool can be modified. If not, you will have to invest in new tooling. Most engineers use casting and 3D printing to validate their designs before investing in hard tooling.

I have no experience with molded parts. Can I still work with you?

Yes, absolutely. Our team will work with you to make sure your design is moldable. For every project, we will provide design for manufacturing feedback so you can understand what risks are present with your design and how to adapt it to minimize those.

What is overmolding?

Overmolding is a multi-step process where a substrate is molded (typically of plastic) and then a second material is molded directly onto the substrate to create one part. An example of this might be a screwdriver handle. The main component of the handle is rigid plastic but a nonslip rubber is overmolded onto it to prevent the user’s hand from slipping while torqueing a screw.

What inspection options are available?

When you start a project with us, we will make sure we understand your inspection needs. In our default inspection, QC will inspect against your drawing and we will provide you T1 samples for your own inspection and approval. We will not provide any documentation. If you need a dimensional report or First Article Inspection report, we can accomodate that in our custom inspection offerings.