Why choose Senturi for CNC Machining?

We are your partner, not just your supplier. We have an intimate network of best-in-class machine shops that can manufacture pretty much anything you throw at us. We never auction out jobs and we will handpick where your parts get built each and every time.

With our process, you get the expansive manufacturing expertise of our network while getting the customer support that is often times missing from most shops. Our team will be in contact at every step of the process so you can rest assured that you will get quality machined parts exactly when you need them.

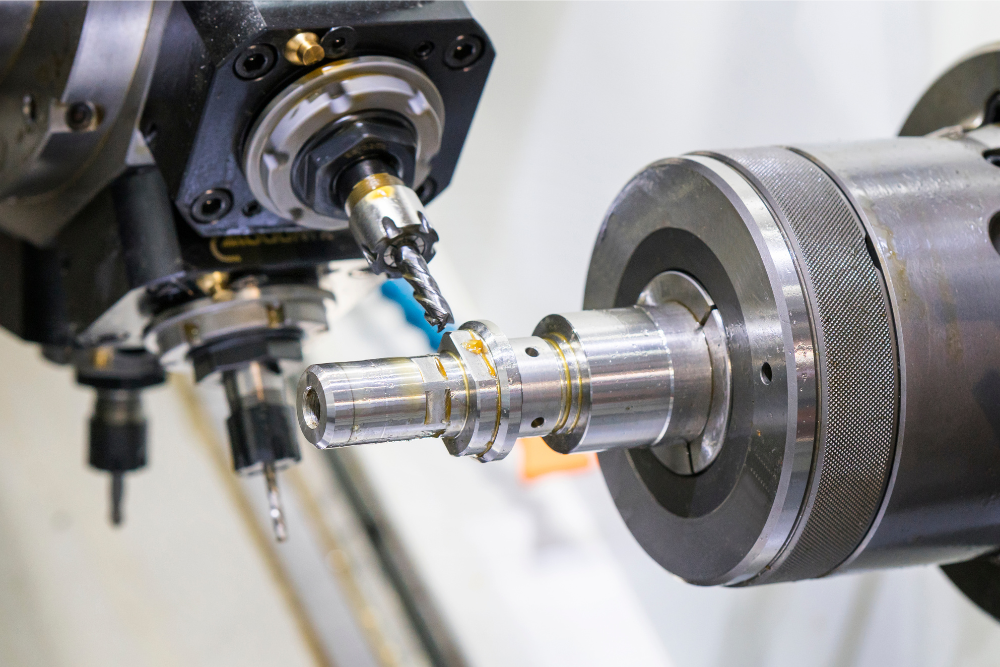

Machining Capabilities

3-Axis CNC Milling

4 & 5-Axis CNC Milling

Swiss CNC Machining

CNC Turning

| Capability | 3-Axis CNC Milling | 5-Axis CNC Milling | Swiss Machining | CNC Turning |

| Max Part Size | 40 in x 80 in x 20 in | 14 in x 24 in x 24 in | Ø 1 in x 5 in Length | ∅ 16 in x 24 in Length |

| Standard Lead Time | 15 days | 15 days | 20 days | 15 days |

| Expedited Lead Time | 6-12 days | 10-12 days | N/A | 6-12 days |

| Standard Tolerance | ±0.005in | ±0.005in | ±0.001in | ±0.005in |

Quick Turn Capabilities

Senturi has quick turn programs with both its domestic and international partners. We want to give you as many options as we can for price and lead time so you can evaluate them against your requirements and choose the best one for your project. Domestic quick turn parts can be delivered in as little as 6 days and international quick turn parts can be delivered in as little as 10 days.

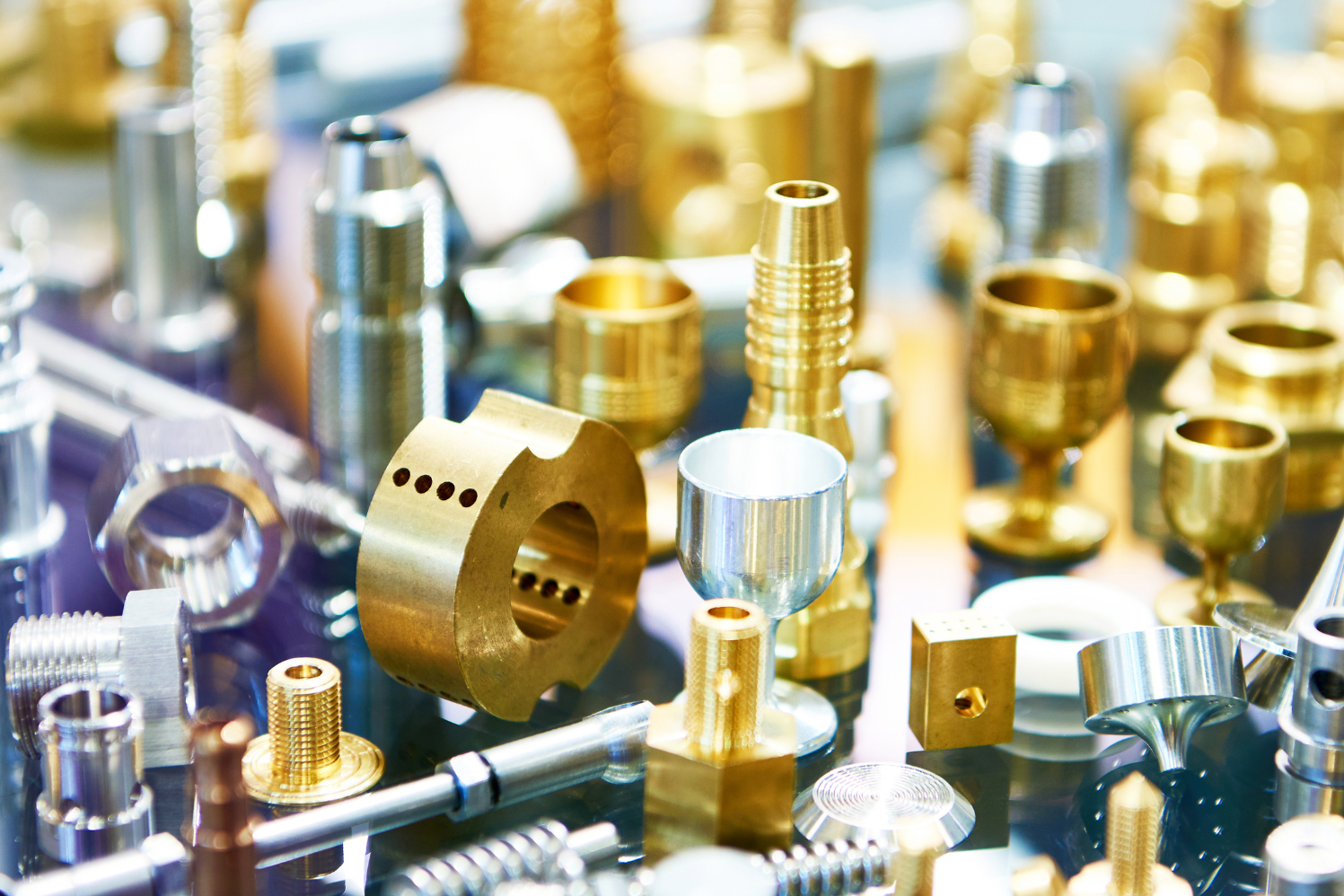

Materials

We machine a variety of engineering-grade metals and plastics. If you do not see the material you need below, give us a call and we can let you know if we machine it.

Aluminum: 2024, 6061, 6082, 7050, 7075, Mic-6

Steel Alloys: 1018, 1040, 1044, 1045, 4130, 4140, 4340

Tool Steel: A2, D2, P20, O1, S2, S7

Stainless Steel: 303, 304, 316, 17-4 PH

Bronze: 642, 645

Brass: 330, 360

Copper: Beryllium Copper, 101, 110 182

Plastics: ABS, PMMA, HDPE, Nylon 6, Nylon 6/6, Nylon-GF, PC, POM, PEEK, PTFE, PVC, Ultem 1000, Ultem 2300

Composites: G10, Carbon Fiber

Titanium: Grade 2, Grade 7

Check out parts made of various materials in our parts gallery.

Finishes

Have unique finishing requirements? We offer an array of secondary processing to make sure your parts are finished to meet all your aesthetic and performance needs. Certifications are available for a fee.

- Painting

- Powder Coat

- Anodize Type II

- Anodize Type III

- Chemical Conversion

- Bead Blast

- Passivation

- Electropolishing

- Heat Treat

- Electroplating

- Zinc Plating

- Black Oxide

- PTFE Coating

- High Polish

- Electroless Nickel

- Part Marking

- Light Assembly

Check out parts made of various materials in our parts gallery.

Frequently Asked Questions

What are the advantages of CNC Machining?

CNC machining provides designers and engineers with a cost-effective method to producing high precision metal and plastic parts. CNC machining biggest advantage is its versatility. It is an effective process at both low and high quantities, across a wide range of materials, and varying complexities.

What if I am not familiar with machining. Can I still work with you?

Yes, absolutely. Our team will work with you to make sure your design is machinable. If we identify any major issues, we will provide you with design for manufacturing feedback so you can make the necessary revisions to get your parts built.

What is Swiss CNC Machining?

Swiss CNC machining can produce small and complex geometries at tight tolerances and rapid cycle times. What separates these machines from other turning machines is the use of a sliding headstock and guide bushing. The sliding headstock feeds the bar stock through the bushing and cutting occurs very close to this point of support maximizing stability. This approach makes Swiss machining extremely effective for turning long, slender parts.

What inspection options are available?

When you start a project with us, we will make sure we understand your inspection needs. In our default inspection, QC will inspect against your drawing but no documentation will be provided. If you need a dimensional report or First Article Inspection report, we can accommodate that in our custom inspection offering.

Can you support expedited lead times?

Yes, Senturi has expedite options with both our domestic and international partners so you have multiple options for your budget. The timeline is dependent on the complexity of the parts and the quantity. Typically, we can deliver expedited parts to you in 5 days if built domestically and 10-12 days if built overseas.